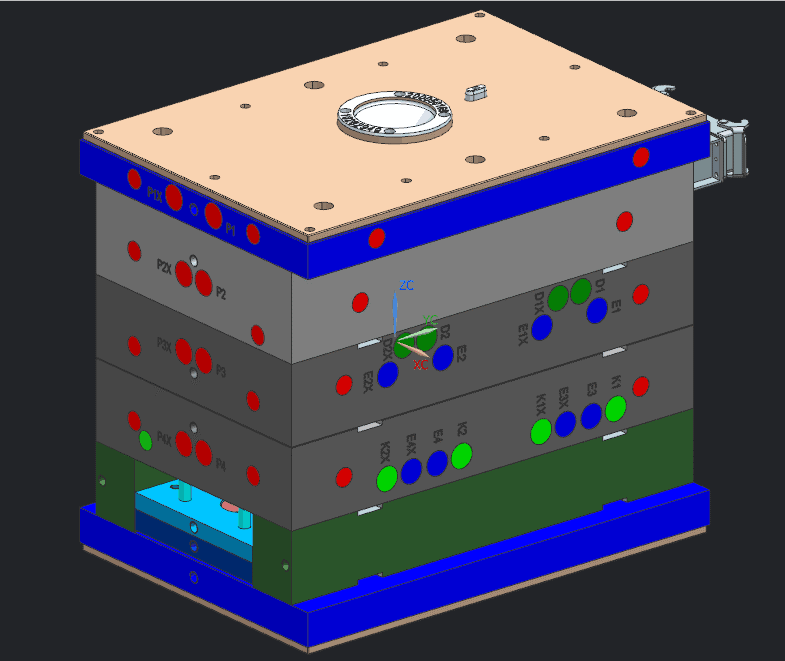

The design of cooling system of injection mold is a relatively complicated work, that is to consider the cooling effect and the uniformity of cooling, but also to consider the impact of cooling system on the overall structure of the mold.

The specific location and size of the cooling system is determined; the cooling of key parts such as moving mold or insert; the cooling of side slider and side core; the design of cooling elements and the selection of cooling standard elements.

Aojie Mould Company starts to analyze these series of problems when the mold is designed. The mold adopts the way of circulating water flowing in every part inside the mold to reduce the cooling time when injection molding, improve the productivity of the products and greatly reduce the production cost.

Mold maintenance Mold maintenance is more important than mold repair, the more times the mold is repaired, the shorter its life; and the better the mold is maintained, the longer its life will be.

Mold maintenance is mainly divided into three points.

1、Daily maintenance of the mold: various moving parts such as ejectors, line position, guide pillar, guide bush mold surface cleaning, water transport evacuation channel, which is the daily maintenance of the mold production.

2. regular maintenance: regular maintenance includes daily maintenance, but also the exhaust slot cleaning, trapped gas burn black bit plus exhaust, damage, wear parts correction, etc. 3. appearance maintenance: the outside of the mold embryo painted to avoid rust, under the mold, the fixed mold moving mold should be coated with anti-rust oil, mold preservation should be closed tightly to prevent dust into the cavity. 7、Nuozhou mould has passed the ISO9001:2000 international quality system certification! Technical requirements are as follows:

1、Analysis of product molding process, mold structure and production process. Guarantee the mold life up to 1 million times or more.

2、Must design the complete mold structure and processing parts, and put forward the assembly requirements and injection process requirements.

3、Cause the plastic parts appearance quality defects (such as shrinkage, etc.) or mold structure problems (such as parting surface setting, gate setting, mold life can not be guaranteed and other problems).

4、Mold appearance:Mold appearance must ensure no rust, no crash marks, no defective module such as defective work.

5.Mold transportation:Mold transportation must be installed with clamping sheet, strong and rust-proof packaging.

6、Mold information:At the same time of mold delivery, a set of mold wear parts and maintenance reference information must be provided.

Post time: May-11-2022